Lamination: What is It?

In lamination, a clear plastic film is bonded to another clear plastic film, a printed product, to strengthen and make it more durable.

Laminate is usually applied to both sides of a piece to provide a protective shield around it. This shield protects the piece not only from smudges and scuffs but also from other things that could ruin its appearance, such as tears, stains, and moisture.

When applied to products handled often between humans, lamination helps your product packaging's colors "pop" more and get noticed.

Matte Lamination: what is It?

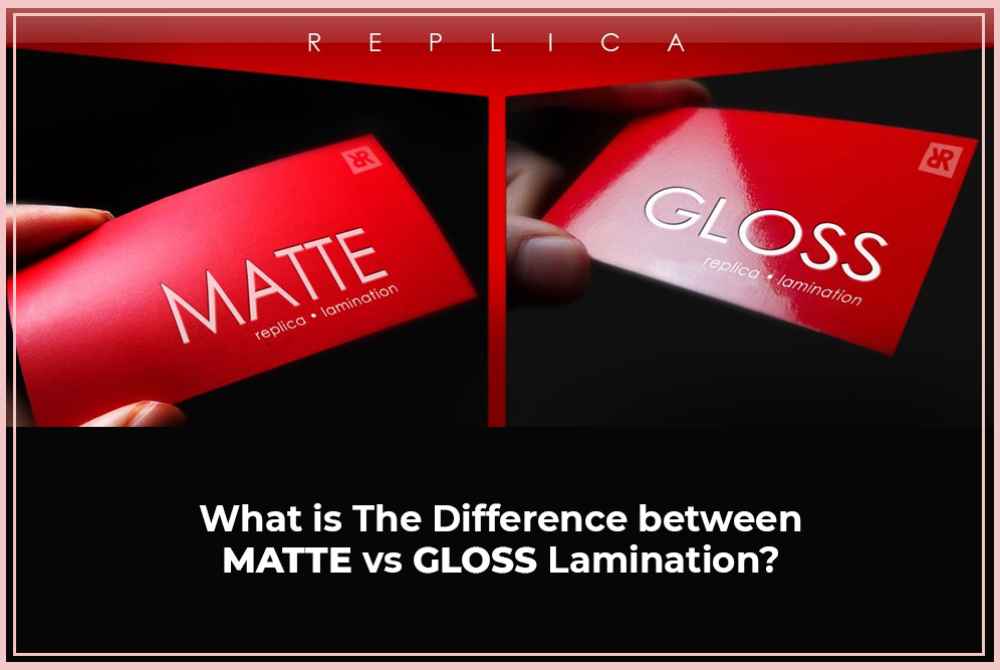

A matte lamination has a softer, more natural look that doesn't reflect as much light as a gloss lamination, making packing easier to read.

Matte laminated packaging does not have the same vivid colors or sharp contrast as gloss packaging, so it could be the best option if you want a more subtle effect.

Matte lamination also has a soft, velvety texture that offers protection.

Gloss Lamination: What Is It?

The glossy lamination enhances the vibrancy of colors by providing a shinier appearance. This technique often adds a touch of sophistication and professionalism to marketing pieces.

With gloss lamination, colors are more vibrant, so laminated packaging is the perfect choice if you want something that stands out on store shelves.

However, there are some instances when you'll want to choose one type of lamination over the other.

The appearance of your packaging is greatly influenced by how it interacts with light. Matte lamination absorbs light, while gloss lamination reflects it, resulting in different visual effects.

When Should You Use Matte or Glossy Lamination?

Matte lamination is best used when:

- The product will be placed under direct lighting. This technique makes the package easier to read at a distance while preventing harsh glare.

- The retail packaging will be handled less. Packaging laminate can withstand some handling; matte laminate is particularly susceptible to scratches and scuffs.

- Your product must look professional and elegant.

- Colors are muted or subtle.

It's a good idea to use gloss lamination when:

- There is a significant amount of packaging handling. Packaging provides extra protection against scuffs and smudges, and gloss can be wiped clean easily. Aqueous coatings are also used to repel fingerprints, so consider your varnish options during the packaging process if this is important.

- Don't worry about the glare if you want the colors to stand out.

- You need to save money. Matte lamination is usually more expensive than gloss lamination (unless your custom packaging firm offers free matte and gloss lamination).

It's All Down To The Consumer (Literally)

Both matte and gloss lamination have pros and cons, and deciding between the two has its own advantages.

The question of this versus that is more about the packaging than the customer's experience.

As more people shop online, your e-commerce packaging has to stand out and grab their attention. In this class, you may think you want "gloss laminate for everything!" If you create a show-stopping piece, you need to think about how you want your customers to feel when they hold your packaging for the first time.

Do you want them to feel like they're holding something sophisticated? Would you like something elegant, luxurious, and classy? Is your goal to make them Feel like they're holding something bold, uncompromising, and vibrant?

Unboxing is now as important as holding and owning the product. Packaging makes a lot of first impressions. Is there a particular impression you want to make with your packaging?

Packaging but the Feel and Look You Want Your Packaging

Is gloss lamination better than matte lamination? The answer is "always. It depends on what you want." You want your product to make an impression on your customers, not just on durability and display.

In addition to the positive impressions gloss vs. matte lamination creates, are there any drawbacks?

Depending on the look you want to convey, both types of packaging have advantages and disadvantages.

Matte lamination has a soft, classy, muted look that can make some colors appear duller or darker colors seem blander. Colors are less noticeable on matte packages, even bright ones. A more subdued coloring approach certainly adds a touch of refinement but also tempers the package's vibrance and tells it to "settle down and behave." If taken to its extreme, this matte lamination packaging implies that the product is inside and could be more exciting.

On the other hand, high-gloss lamination allows you to create a very bright centerpiece that can Assert itself loudly, boisterously, harshly, and glaringly. In accordance with your desired impression, this could be similar to a visual overload for consumers.

Whether you use digital or offset printing, your color combinations greatly affect the results. Experiment with different color combinations and lamination styles to find the combination that truly speaks to you and your customers.

Your lamination should balance the impression you want to make and the durability and "presence" you require.

Do You Have Any Questions For Me?

Consider matte versus gloss lamination when developing the perfect packaging product.

When creating custom packaging, many important decisions must be made. It's much more than simply printing a package. However, you can make them with others. We have years of experience working with matte and gloss lamination and various packaging types, products, and print needs.

Don't hesitate to contact us with any questions, concerns, or ideas about your packaging. We aim to help you make an impression on your customers while attracting attention, interest, and engagement and providing an unforgettable unboxing experience.

With Luxury Custom boxes and Packaging Ideas, you'll be more confident than ever that your product's packaging is designed to succeed.