How Do Rigid Boxes Work?

A rigid box is made from sturdy paperboard, provides incredible product safety, and is typically printed with elegant finishes for a luxurious look.

Rigid packaging boxes combine two parts: sturdy cartons and flexible paper wrap. This wrap, in addition to premium printing techniques, is customizable to reflect your brand's identity and offers a unique branding experience.

In addition to shielding products from scratches and dust, some custom rigid boxes have lining interiors that add an elegant touch.

The unique selling point of rigid set-up boxes is that they are always in 3D form, requiring no assembly before filling. This sets them apart from collapsible boxes, which some brands are developing. While most rigid boxes cannot be folded to lay flat and reassembled, their 3D form ensures convenience and ease of use.

While not as durable as customized rigid boxes, corrugated boards offer a different kind of versatility. They are lightweight, foldable, and more versatile than cartons. These boxes can be customized with stand-up, point-of-purchase, and point-of-service displays, making them a great choice for creative packaging solutions.

Rigid Boxes Have Many Benefits.

Why are rigid gift boxes a great option for your business?

1. The Designs Can Be Customized.

A custom rigid box can be used in various ways as part of your luxury retail or e-commerce packaging marketing strategy. Depending on your target buyers, you might prefer a unique shape with a bright, fun design or a more conservative layout.

In addition to chipboards coming in different thicknesses, specialty papers, printing techniques, coatings, and finishes can be used to customize the wrap with your logo and brand name.

2. You Don't Need To Set Them Up

Except for collapsible models, our customized rigid boxes don't require assembly, effectively reducing labor costs after delivery and putting you in control of your finances.

3. They Raise Brand Awareness.

Choosing rigid boxes that stand out from your competitors can increase sales. Boxes can be designed with clear windows, sticker labels, or a specific structure that makes handling and unpacking enjoyable.

4. They Improve The User Experience.

Consumers will likely look at your packaging when they see or touch your merchandise. Adding custom packaging boxes to a product can enhance its visual and tactile appeal. Your brand's value is increased as a result of this elegant appearance.

The rigid packaging box gives prospective and current customers a well-rounded experience from when they examine it (online or in a physical store) until they receive it via delivery or take it home.

5. You Can Boost Your Credibility By Using Them.

You will appear more professional and trustworthy when your logo, brand name, artwork, and product details appear professional and reliable.

6. Their Purpose Is To Protect Against Damage.

Rigid boxes are designed. Their contents must be protected during storage, handling, and long-distance transportation. Including oil bottles and tinctures, the inserts can securely hug the items so they don't arrive damaged. The lids are designed to keep items safe and secure. Inside panels can also keep sweets fresher for longer.

7. It Is Possible To Repurpose Them.

Many luxury packaging pieces can be reused as drawer separators or storage containers featuring resealable lids or magnetic closures if kept as keepsakes. A well-designed, high-quality packaging box can become an indispensable part of one's work desk or closet for a long time, holding everything from souvenirs And jewelry to important documents and printed photos.

8. They Support Brand Loyalty

Refusing rigid packaging boxes for other purposes, such as building a following, is possible. Environmental advocates who are very particular about packaging boxes can be attracted to eco-friendly materials.

Rigid Packaging Shouldn't Be Used In Certain Situations.

You may not want rigid boxes if:

1. You Have a Large Product to Sell

When it comes to small to medium products, rigid setup boxes can provide superior product safety. but their shape may be better for large home appliances, whose heavy weight may pressure the edges. A better alternative may be high-end corrugated packaging.

2. Large Expenses Still Need To Be Added To Your Budget.

You'll discover that rigid boxes cost more due to more expensive and thicker materials, a more specialized process, and higher shipping costs. If you aren't ready to invest in rigid packaging, your manufacturer can use a high-quality folding carton or corrugated box for your design.

3. Time Is Of The Essence.

If you have a tight schedule, you may use carton boxes, as rigid boxes take longer to produce.

Rigid Boxes: Types And Use

There are two types of rigid box packaging: two-piece and hinged.

1. Top-loading or Telescope Boxes

Having Cornered

A telescope box features a lid that covers the base halfway (partial telescope) or almost to the bottom edge (full telescope). Several full telescope lids have thumb cuts or semi-circular cutouts, making lifting them easier.

An example of a partial telescope box is a shoebox with a one-inch deep lip. Our windowless shirt boxes and luxury cosmetic packaging follow this structure, as do many commercially available high-end gift boxes. Various shapes are also possible.

A partial telescope box is also known as a neck or shoulder box (others call it a shoulder box). A dual-base box has an inner tray (also known as a neck insert) higher than the outer tray. The protruding part of the tray is called the neck, and the top edge of the outer base is called the shoulder. A shoulder rests on the lid. Some shoulder boxes have an extra-long neck, causing a gap between the lid and the base.

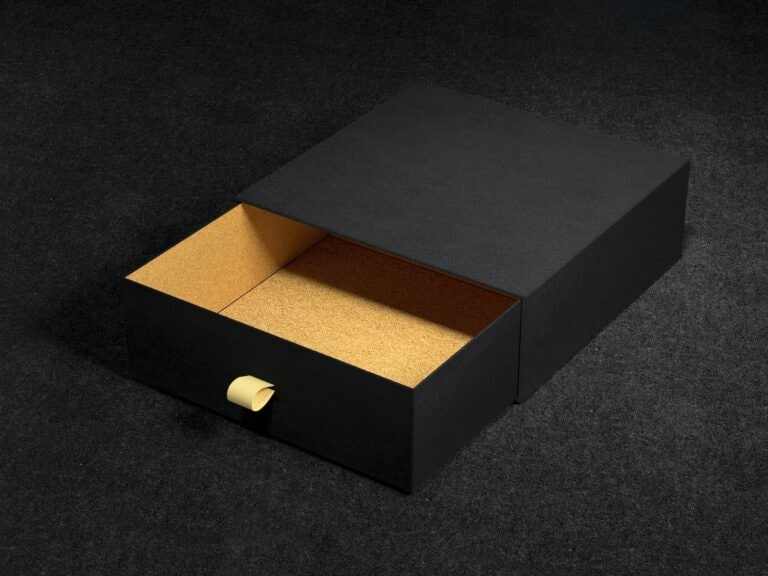

Drawer-style boxes are variations of full telescope boxes. They are also known as the shell and slide or the tray with a sleeve. The box looks like a traditional matchbox. It has a slipcase that covers the "tray" of matches rather than a lid. Drawer-style boxes are suitable for items that should be laid down rather than upright to prevent damage or preserve their contents. Smartphones, jewelry, and cosmetics are examples of such products.

Having No Corners

These cylindrical rigid boxes, called rolled-edge tube packaging (or simply tube packaging), feature telescopic or shoulder-neck openings. They are perfect for packaging bottles, markers, and other circular-shaped items, as well as powdered goods and irregular-shaped items. Brands can also consider metal packaging an alternative.

Our rigid tube boxes are designed with the highest-quality materials, offering a choice of plastic or metal lids. Their interiors can be customized with plastic inserts, which are ideal for beauty products or foils, ensuring the safety and quality of the packaged goods.

2. Boxes with Hinged Lid

The Hinge Is Covered With A Cover.

A hinged lid box has a cover permanently attached to the base. A magnetic strip or other securing material is used to secure it, or it closes due to its weight. Some of these boxes, such as the flip-top or cigar box, don't have a lip that covers the base. Book-style boxes have covers similar to cigar boxes—the flap extends slightly beyond the base, giving the box the look of a hardcover book when closed.

A clamshell design has a lip that extends partially or to the base's bottom edge. In some hinged lid boxes, an inner lining covers the hinge joint.

Hinge without cover

Rigid Boxes: Different Finishes

In addition to having versatile structures, rigid boxes can be finished in many ways, from how the wrap surrounds the box to how the wrapping material feels and looks.

A Partial Finish Vs. A Full Finish

A partial-finish rigid box is one in which the wrap only covers the outer surface of the lid and tray. The chipboard's interior is mostly bare, except for the lips of the wrapping paper folded and glued to it.

The chipboard is wrapped in a rigid box with a full finish. Depending on the color of the inner wrap, it may be white or another color.

Exterior Aspects

For those looking for fancy packaging, there are several options available.

1. The Coatings

There are several types of coatings:

A varnish is made of clear ink, creating a thin satin, matte, or glossy layer on the wrap. Flood varnish can be applied to the entire sheet or a specific area (spot varnish).

Your boxes will have a glossy or matte finish with an aqueous coating, making cleaning dirt and fingerprints easier. Compared to varnishes and ultraviolet (UV) coatings, they're also scratch—and scuff-resistant. Food and beverage boxes are usually coated with this type of coating since it is food-safe.

Sunlight or UV light is needed to harden UV coatings quickly. Although they provide the highest gloss, foil stamping cannot be applied to them. UV-coated sheets must be completely hardened before embossing.

2. Laminate

Water- and moisture-resistant wraps are laminated with polypropylene or a very thin plastic film, reducing small cracks and creases. Because of its higher level of protection, polypropylene is more expensive than varnish, which is why it's mostly used in high-end luxury packaging. The lamination on most custom luxury boxes is matte rather than glossy. This is the best coating if you add foil stamping, embossing, and spot UV to your outer design.

3. Foil Stamping

Foil designs are applied with heat and pressure. You can highlight your brand and logo with the bright metallic foil.

4. The Embossing and Debossing Process

Embossing and debossing can enhance the texture of high-end gift boxes and fancy packaging, making them more eye-catching and appealing to consumers. The embossing and debossing of foil-stamped materials create depth.

5. Crowding

Flocking is the process of creating velvet or suede-like textures on rigid boxes. Many short fibers include cotton, wool, rayon, and synthetic fibers. Depending on your preferences, they can be dyed in any color. In some cases, this process can also be applied to insert surfaces.

Flocking fibers are electrically charged before spread over an adhesive-coated material, as seen in the following video.

What Is the Process of Making Custom Rigid Boxes?

For luxury or high-end retail packaging solutions, brands and sellers turn to rigid box manufacturers. A typical creation process consists of three stages:

1. The Conceptualization Process

An expert rigid box packaging consultant can assist contracting companies in developing the right design to meet their needs. Some manufacturers' in-house design and engineering teams can also handle conceptualization and prototyping.

Designers should be aware of the following points at this stage:

An item part of a broader product line should be packaged according to an established design.

It must hold many items in a particular way if the box has many items.

The size of a box may be affected if a certain artwork appears on it.

You are incorporating advice from your retailer, who will ultimately decide which of your products to sell.

Once the concept and budget estimates have been presented, reviewed, and approved, a box maker can create the template. A rigid box wrap requires artwork from the contracting company.

2. Manufacturing

A combination of machine and hand production is used. Before printing, the wrap undergoes lamination or other treatments requested by the client. In contrast, chipboards are scored and cut to size and shape. To keep the sides upright, either machine (quad stayers) or staff (or both) fold the tray or base of rigid boxes and apply adhesives at the corners.

Pre-trimmed wraps are lined up on a conveyor belt in packaging companies with fully automated systems. An arm places trays on each wrap's glued surface. After passing through the plunger, the tray with the wrap beneath it is glued evenly on its exterior.

3. Shipping

Packing materials themselves should also be protected during shipping. This aspect should be considered and included in the design process.

The Testing Process

About 11% of shipped goods are damaged. In this case, the brand offers a discount, spends on return freight, and loses profit. Customers' trust is adversely affected when boxes—or worse, their contents—are dented, scratched, or torn.

Testing is therefore required to complete the Packaging production for rigid box packages and other high-end products.

Analyzing Dimensions

The dimensions of your chipboard must be tested even before it is wrapped. The chipboard folded on an automated assembly line must have the precise length, height, width, or diameter to ensure that the wrap covers it partially or fully, depending on the design specifications. In addition to meeting the prescribed dimensions, inserts and fillings must also fit within the product.

Labels and stickers are also applied automatically in mechanized production. Rigid boxes should have accurate dimensions to place seals and other adhesive-based materials correctly.

Tested by Dropping

Contractors can determine how well the box will hold up in an accident. The most popular procedure is a drop test developed by the International Safe Transit Association (ISTA).

A machine drops the box from varying heights on a hard surface during the test. The product is placed inside the box. You can test the box's corners, edges, and sides. The manufacturer or supplier is responsible for analyzing any damage caused and devising a solution. Once the improved box is available, the test is repeated.

Drop test machines are available for various package sizes and weights.

Avoid These Common Mistakes When Designing Custom Rigid Boxes.

There are several disadvantages to using custom rigid boxes:

1. Oversized Packaging

Buyers will be turned off if a product is small inside a big box, no matter how fancy the packaging is. Negative online reviews or lawsuits can result from disappointment over a false impression.

2. Insufficient Differentiation

It would help if you designed custom rigid boxes that are eye-catching and different from your competitors. Thoroughly research your segment and ask your design team for suggestions.

3. A Lack of Adequate Protection

Liquid-filled bottles may need grease barriers in their boxes. Waterproofing should also be considered when designing custom rigid boxes for outdoor display.

4. Not Pet-Friendly or Child-Friendly

Your packaging should include instructions for human and pet parents if you target adult clients of different ages. Hazardous substances or choke hazards should be clearly stated.

Several Factors Cause High Prices

Rigid boxes can cost as much as $4 to $5 per piece, which is more expensive than corrugated boxes (under $2 to $3) or folding carton boxes (under $1). In the previous sections, we mentioned and indicated that higher costs may arise as a result of:

A Materials List

Custom rigid boxes are made from chipboard, which is thicker than regular, foldable cartons. Natural chipboard is the cheapest and comes in various colors, including white and black.

Wrapping paper and finishes play a significant role in the pricing of custom rigid boxes. The amount of paper required to cover the chipboard, especially for full-finish boxes, directly influences the cost.

Finishing, metallic, neon or other specialty ink is more expensive than regular ink. Larger surfaces naturally require more materials, and the total cost also includes additional elements like labels, magnetic strips, or ribbon pulls.

The Construction Process

Your final bill includes the tooling cost for producing each custom rigid box, including dies for cutting its shape, foil stamping, embossing, and debossing, as well as print cylinders, plates, and molds. The fee will increase if your packaging box has a unique shape and many parts and involves many colors and other printing techniques. Molds and cutting dies must be used separately for inserts.

Manufacturers Fold parts of your custom rigid boxes, paste their sides, and wrap them with special machines. Tissue, cardboard, foam, or plastic packaging may require manual labor.

The Volume

Economies of scale also apply to the packaging industry, so small-run custom packaging projects will cost more than large ones.

The Transport Sector

Most rigid custom boxes are not collapsible and cannot ship flat, resulting in higher shipping fees. Rising fuel costs will ultimately affect how much you must pay couriers or third-party delivery services.

Space for Storage

In their final form, custom rigid boxes require a lot of storage space since they arrive pre-assembled. Find out if your packaging company offers managed inventory services. This involves keeping an agreed-upon stock level and shipping just in time or when needed. You can also survey any unused space in your business warehouse.

Cost-Cutting Strategies for Rigid Boxes

Consider these workarounds when delivering rigid boxes on a budget:

1. Make Sure the Sizes And Thicknesses Are Standard

Complex structures are inevitably more expensive. If you use a standard size and thickness, your manufacturing partner will have to do less customization. Chipboard is bulk or volume purchases, which may be easier for them and sufficient to cover your rigid box order. As a result, you will experience lower costs, they will begin production earlier, and the turnaround time will be shorter.

2. Make Your Design Smaller.

Do you want to stay true to your original concept? It might be possible to reduce the graphics and shorten the text to fit them into a smaller cardboard package. You can also reposition the product differently or disassemble it to see if a smaller box will work. Using smaller rigid boxes allows you to display more products on a store shelf simultaneously.

3. Choose Lighter Materials

Know your chipboard thickness options. With the design or manufacturing team, identify ways to make a thinner version to serve your advertising and functional needs.

4. Print Low-Volume Jobs Digitally.

While digital printing is less high-quality than offset printing, it is more cost-effective, especially if your design is simple and minimalist.

5. Diminish Embellishments

Consider adding a viewing window. Cutouts can be a cheaper alternative to embossing or foil stamping, especially if the primary package includes artwork, such as the label on your product's bottle, plastic casing, etc.

Foil-stamping and embossing should be reduced in the areas where they will be applied. These treatments increase the cost per square inch. The finishes you choose for your box should be limited to the essential parts.

Choose a low-gloss finish and water-based coatings. UV and glitter coatings are more expensive. Low—or semi-gloss finishes are an excellent alternative to lamination, which is known for its moisture resistance.

6. Make Use of Paper and Tissue Paper Inserts.

Compared to foam padding, these materials are more affordable. In addition to gadgets, cosmetics, luxury candles, and more, you can use cardboard inserts with slits to support rigid setup boxes.

7. Get Quotes from Different Suppliers.

You should ask three or four reputable packaging solutions companies for a quote, specifying your materials and size. Decide which company can do the job at a lower cost without sacrificing quality.

Rigid Box Makers: What to Look for

Custom rigid box suppliers should have the following characteristics:

1. Produces Rigid Boxes

The number of manufacturers of folding cartons currently outnumbers those of rigid packaging. A custom carton box maker can do the job for you by outsourcing the work and charging you an additional fee. If you want rigid packaging, choose a rigid packaging specialist. Actual samples are preferred, not just prototypes.

2 . Employs In-House Designers

Your first step should be finding a producer with a team to help you design custom packaging. You can minimize delays and improve coordination by dealing with one company from conception to production.

3. Communicates Well

Take a look at client reviews. Reviews indicate that a company listens well to clients' needs and wants, resulting in low error rates. Your questions regarding how boxes are made, minimum order sizes, and turnaround times should be answered promptly. They should also offer a practical solution.

4. Supports Environmental Sustainability

Environmentally conscious brands are attracting today's consumers. When a rigid setup box manufacturer is Forest Stewardship Council-certified, it uses paper products from responsibly managed forests. In addition to using recycled fibers, water stewardship, and renewable energy, you can choose custom product packaging manufacturers that practice these practices.

Trends and updates in the market

The rise of work-from-home opportunities has made it possible for more people to shop online for various goods, including luxury goods and gifts. Paper packaging is still in high demand despite the growing popularity of bioplastic, which releases polluting methane gas and may affect food quality.

E-commerce growth in the coming years is expected to be driven by the personal use and gifting of video games, confectionery, wine, other beverages, and personal care products. Luxury rigid boxes are used to package clothing, shoes, watches, and jewelry, Particularly among millennials and Gen Zers. According to forecasts, approximately $5.4 billion will be generated by this box type by 2030. The custom two-piece rigid setup boxes market is expected to reach $268 million by 2025.

Boxes that collapse rigidly

Several manufacturers now offer foldable rigid setup boxes. Because they can be stored flat, they offer the convenience and versatility that custom carton boxes can provide.

Packaging That Makes Sense

Digital technology will continue to be integrated into custom rigid boxes by more and more brands for better quality and customer engagement. A few examples are as follows:

1. Electronics That Are Printed

When consumers bring their smartphones close to an NFC tag, they can receive more product information, verify authenticity, detect tampering, and even detect temperature. Brands can also track orders using radio-frequency identification (RFID) and NFC stickers. Imagine the possibilities with LED and OLED lighting devices in your custom packaging. When activated by hand pressure or a smartphone, these innovative, flat, nanometer-thin types of lighting can make your business logo, product name, or packaging glow or create a holographic image without needing a battery. It's a truly exciting and unique feature for your Packaging.

2. Real-Time Augmented Reality

By including a QR code in the packaging, brands can offer buyers a captivating experience. They can view the product with animation and sound effects or play a mini-game where virtual objects appear out of thin air. The visual appeal of AR-enabled packaging is reportedly better than regular packaging, making your product stand out and drawing in potential customers.

Luxury Rigid Packaging Boxes for Your Customers

Many Fortune 500 and Inc 5000 companies choose Luxury Custom Boxes. Its sky-'s-the-limit attitude, fast production times, and affordable pricing will help you make your custom packaging stand out. Dedicated packaging specialists will guide you through every step of the custom packaging process.