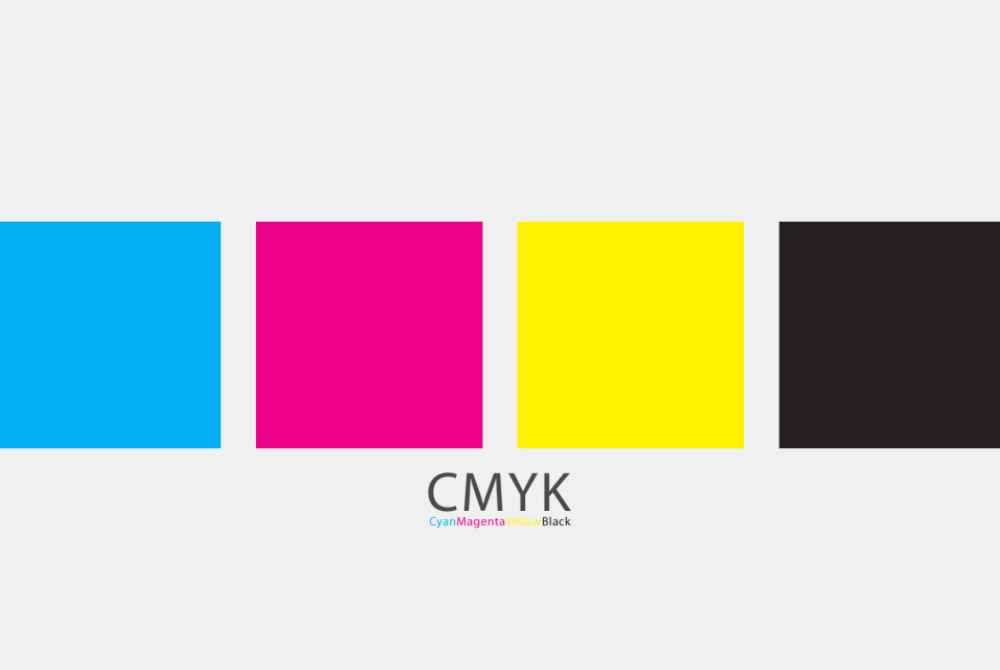

A CMYK print comprises Cyan, Magenta, Yellow, and Key (Black). It is used for printing. The CMYK color model begins with white ink, and then layers of cyan, magenta, yellow, and key (black) ink are added to reduce the brightness.

A CMYK print comprises cyan, magenta, yellow, and black ink. Blending these colors makes it possible to create about 16,000 variations using the CMYK system. The color wheel shows:

Most people consider cyan to be a color between blue and green. A tropical ocean's blue color resembles sky blue or aqua blue.

- In terms of color, magenta falls between red and blue, but most people consider it closer to red than blue. It is similar to fuchsia, hot pink, or deep pink. This color is associated with bougainvilleas and orchids.

- Sunflowers, daffodils, and sunshine are yellow, including lemon yellow, canary yellow, and gold.

- Black is found in coal, volcanic rock, and some gemstones, such as obsidian and onyx. The black ink plate provides fine details, depth, and contrast in the resulting image, which is why "K" is also called "key." "Key plate" refers to the black plate in another way.

It is theoretically possible to create black by mixing cyan, magenta, and yellow. However, this combination produces a muddy dark gray. In addition, a three-color blend soaks the paper in ink, causing it to take longer to dry.

What is CMYK?

A commercial offset printer like Luxury Custom Boxes separates your packaging design file into component colors through color separation.

As each CMYK ink color has its printing plate, the ink transfers or offsets from this. The plate is placed on a rubber blanket and then on the ground paper. The dots overlap until the four-color process or process printing is complete, producing solid and continuous colors.

On the other hand, digital printing takes a different route. It skips the color separation step, with ink going directly onto paper. This direct approach, without needing plates, makes digital printing a cost-effective option for smaller print runs.

Here's how it works: your file is copied by the printer. Then, individual CMYK color droplets are strategically placed to create the illusion of a colored image. Inkjet printers use ink, while laser printers, commonly used in commercial applications, use toner.

System of RGB and Pantone

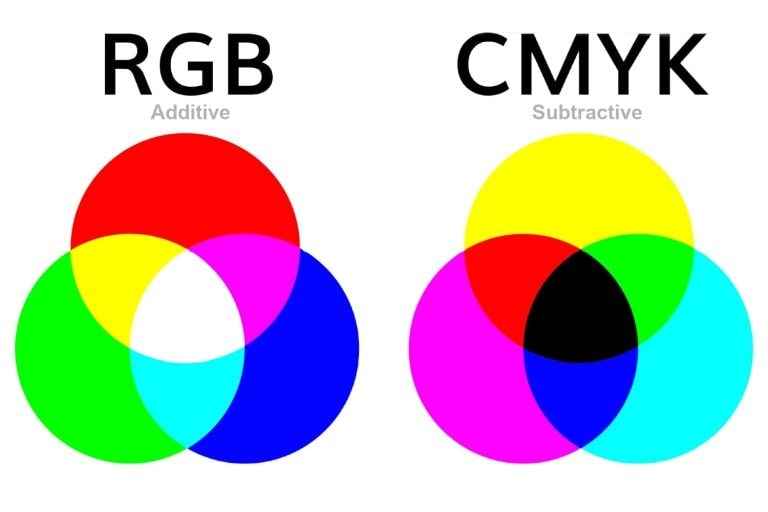

Our understanding of CMYK can be improved by comparing it with RGB and Pantone color models.

CMYK

Designers often use RGB, which stands for red, green, and blue, as desktop colors. These colors represent the colored lights on electronic displays, making them ideal for digital media such as videos, websites, and apps.

Furthermore, this color model offers the largest range of colors, with 16.7 million available. Due to CMYK's narrower color gamut, discrepancies occur between screen and print colors.

The RGB Vs. CMYK Color Model: Additive Vs. Subtractive

It's important to understand that RGB is an additive color model, while CMYK is a subtractive color model.

The RGB model, based on combining red, green, and blue light intensities, is the foundation of electronic screens and digital displays. This combination results in pure white, and the absence of light creates black.

Contrary to this, CMYK is a subtractive color model. In contrast to electronic screens, paper isn't transparent and doesn't let light pass through. White can be seen by applying less color. The paper receives fewer ink dots when images are lighter.

RGB images should be converted to CMYK rather than RGB to print accurately, as CMYK inks reflect light instead of emitting it.

It is called Pantone.

The Pantone Matching System (PMS) uses a numbering system to identify colors accurately and quickly for printed materials, fabrics, and paints. There are 2,161 Pantone colors, each with a unique code corresponding to a premixed ink formula for consistent color production. The CMYK and RGB models don't support fluorescent and metallic colors.

The staff of a professional printer adjusts the digital printer's colors to match your PMS swatch when you ask them to match your specific PMS colors.

The color of a spot

Spot or solid color refers to a color printed on paper using premixed ink to match a PMS instead of CMYK, which consists of four layers (one for each color). Spot colors are blended before printing, not during.

There are two types of spot colors: coated and uncoated. Coated Spot Colors are names or numbers followed by a C or U, which refers to the kind of paper stock on which the spot color is printed.

Printing in CMYK and Spot Colors

The following tips will help you decide whether to use four-color or spot-color printing:

Printing in CMYK

Process printing is ideal in projects involving so many colors; several spot inks would be impractical and costly. Photographs and paintings in full color and very complex colored images are examples.

CMYK printing is also cost-effective for low-quantity orders with multiple hues and gradients. Colors may differ slightly between spot colors and color matching. The extended color gamut of some printers To improve brightness and realism, it includes orange, green, and violet colors.

The color of a spot

Spot color printing is best used If you need a few (one or two) exact colors, such as your brand colors and business logo, and if you want colors outside of the CMYK range, such as pastels, metallics, and fluorescents. The cost of spot colors would be higher per order since they require specific ink formulations and separate plates.

Spot and CMYK printing

If you need to print an image (CMYK printing) and Place your company logo or product name (spot color) close together, you can use both techniques simultaneously. Another example is adding clear varnish to portions of a full-color image to increase its intensity.

Color Accuracy Tips When Previewing CMYK Colors

Since RGB can display more colors than CMYK, the way you see a design on screen may not be accurately reproduced by CMYK printing. Following these tips will reduce the discrepancy between them:

Start with calibration. Make sure your monitor is calibrated and perform soft proofing

During manufacturing, laptop and PC manufacturers adjust settings for film viewers and gamers, resulting in high brightness, high contrast, and saturated colors.

Working on packaging designs requires recalibration. The brightness or luminance of your display should be adjusted to match your color standard ("color profiles" on Mac). When designing and editing on a bright monitor, your printouts may appear dark. Calibration tools are usually built into most monitors.

The recommended white point or white balance for LCD monitors is D50. The white point determines the coolness or warmth of your whites.

Soft Proofing

You should check the color management system in your software. With Adobe Photoshop and Illustrator's soft proofing feature, Your artwork will appear CMYK when printed.

Refer to color guides and swatches.

In checking designs and images on screen and paper, printed samples of colors are handy.

Test-print the document

Get printed proof to discover color problems early and avoid surprises from your printer. Once your digital file has been sent to your printing partner, you can include the printout closest to your envisioned colors.

Ensure your ink and paper are high quality to avoid faded results. Additionally, you should check the nozzle and cartridge of your printer to see if there is banding. You can also have a test copy made by a print shop.

Printing Your File

After learning to display your packaging design on your screen, you must prepare your file for the printer.

CMYK Conversion

It's important to check your packaging design and convert it to CMYK if it's in RGB mode or send it to an industrial printer. The conversion steps depend on your software and how you want to convert. CMYK conversion steps are listed below for the most popular platforms.

InDesign & Photoshop

- Click on the image file you want to open.

- On your screen, click on "Image.".

- Click CMYK in the "Mode" drop-down menu.

Acrobat Illustrator

- Your image file should now be open.

- On the top menu, click "File".

- Choose CMYK from the "Document Color Mode" menu.

Acrobat InDesign

- Your image file should now be open.

- Choose "Export" from the "File" menu.

- The PDF/X-1a:2001 format can be selected from the following list of options. Colors are converted to CMYK automatically.

CMYK can't accurately represent all RGB colors, so converting from RGB to CMYK may result in some color data loss.

How To Communicate With Your Printer

Before sending your design, determine the printing company's requirements, limitations, and preferences. Inquire about your printer's artwork guidelines, which usually include the correct file format, size, resolution, color system (some printers have a unique PDF Preset), and their expectations and deadlines.

Technology advancements have allowed some printers to print files with specific RGB profiles, such as sRGB IEC61966-2.1. Your file is converted to CMYK before printing.

.CMYK File Formats

Please ask your printer for the file format required for your print project. Below are a few of the best file formats:

Illustrator (.ai)

Vector-based, scalable designs are made possible with Illustrator, making it a standard source file for CMYK printing.

Portable Document Format (.pdf) for storing documents.

Unlike other formats, A PDF document preserves all the color and formatting information and can be edited with raster and vector images. Its compatibility with most programs makes it ideal for CMYK printing.

A .eps file is an encapsulated PostScript file.

As an alternative to .ai, EPS is a vector-based file format.

CorelDraw (.cdr)

Besides images, CorelDraw files can also contain text, shapes, and effects. In addition to .ai, .pdf, and .png, the CDR format can be converted to .eps and .tiff.

Tag Image File Format (.tiff)

Virtually all image editing and page-layout programs support the raster image file. In this format, you can choose between CMYK and spot colors.

Consistent CMYK Printing Requires Reliable Custom Packaging Manufacturers

As you create custom boxes, get up to speed with our ultimate packaging terms and definitions guide.

The U.S. packaging market is predicted to grow by 2.88% to $222.59 billion by 2028, maintaining its status as a leading growth driver for offset printing presses. Digitization has penetrated this printing method, making it competitive with digital printing. Nowadays, computers create printing plates, which are exposed to lasers to improve image quality.

Furthermore, analysts predict a 5.19% growth in the North American cardboard market until 2027.

Color plays a pivotal role in buying decisions, with 85% of consumers citing it as the top influencing factor. This underscores the importance of your printer delivering consistent quality to meet these color expectations.

Luxury Custom Boxes ' customers and brands have consistently relied on our high-spec manufacturing process, from display and showcase exhibit packaging to shipping and mailer boxes, corrugated Packaging, and custom labels and stickers. This reliability has made us a trusted partner for their marketing needs.

Our offset printers accept CMYK and PMS colors. If your design is in RGB mode, CMYK conversion is available. Here are some artwork guidelines to help you prepare your file. We'll also show you digital proof before printing so you can make sure the colors match your initial choices. In addition to offset printing, we offer UV coating, foiling, and embossing/debossing.

Many Fortune 500 and Inc 5000 companies choose Luxury Custom Boxes. Our sky' s-the-limit attitude, fast production times, and affordable pricing will help you make your custom packaging stand out. Contact us today, and our specialist's custom packaging process will guide one of our packaging steps.