Pantone Matching System History

Two brothers, both advertising executives, founded Pantone in the 1950s. Lawrence Herbert, a recent college graduate who uses his knowledge of chemistry to categorize and organize the company's products, printing inks and pigments, joined the brothers a few years after founding the company.

Let's say you have a product. One printing company will print your logo at one location, and another will produce your custom packaging nationwide.

Are you sure both printers will use the same shades and colors in your logo and packaging?

Enter the Pantone Matching System (PMS). Recognizing the common issue of color variation in CMYK printing, Pantone stepped in and created a system that revolutionized the industry, providing a consistent color numbering system.

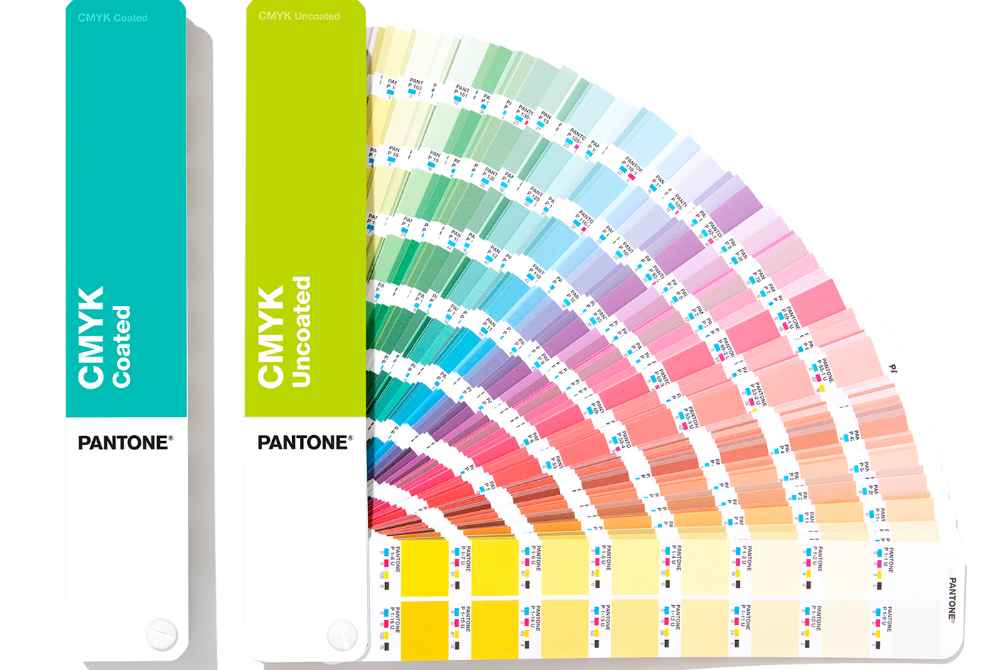

An entire sheet of PMS can be dedicated to different shades and variations of a single color. By joining several sheets together, they can be arranged into a "fan." PMS allows print designers to match colors and standardize their printing wherever they are by coding by numbers.

Matching Pantone Colors in Two Ways

Pantone has two matching systems: one for packaging and one for products.

Pantone's palette of almost 5,000 colors is pivotal in product design and retail packaging. It helps to attract customers with vibrant hues and create a unique brand identity with 'market-relevant colors'.

Furthermore, a color's appearance is influenced by the material on which it's printed.

Depending on the material, some colors don't appear at all, or they look awful and not what a product creator would want. The Pantone Matching System (PMS) is designed to guide designers in this regard, as it separates its palette into two distinct systems. This not only informs designers about what colors can be reproduced on what materials, but also whether they will print brilliantly, thereby ensuring practical application.

PMS (Pantone Matching System) palettes

PMS palettes vary depending on what you'll be printing on.

Whether you're working with a Pantone solid palette, a Pantone process palette, a textile palette, or a plastic palette, the versatility of PMS palettes ensures that you can determine the colors suitable for your specific printing material.

There are several benefits to using a PMS. It is the world's most widely used color-matching system, so your printed materials can be reproduced almost anywhere. Printers can easily match those colors to their Pantone color code, ensuring consistent results.

The PMS also has an excellent color range. Other systems exist, but Pantone's are more precise and accurate. Since its system is so popular, Pantone selects a new color to represent the year each year. With names like "Tangerine Tango" and "Mimosa," they sound like flavored cocktails rather than colors. When you consider it, they are really like cocktails—eclectic mixes that are like flavors for the eyes.

Understanding the Crucial Difference: PMS vs. CMYKUnderstanding the difference between PMS and CMYK begins with understanding spot and process color. Logos are examples of things that use spot colors. It is possible to match a Pantone color name or number on a printing press to match the distinctive yellow of McDonald's Golden Arches.

In contrast, CMYK colors are created using a mix of Cyan, Magenta, Yellow, and Black. As a result of the differences between printing presses and a variety of other factors, one cyan may not match another, resulting in substantial color variations.

Depending on the printer, the press operator's experience, and other factors, that distinctive yellow may look washed out or dirty. Your printed colors will also depend on whether your printer uses digital or offset printing.

In contrast to CMYK colors, Pantone colors are guaranteed to be uniform because they can be selected based on a globally understood name or code.

Can Pantone Be Converted To CMYK? Are You Able To Convert From CMYK To Pantone?

It is possible to do this, but it can be challenging.

Significant differences exist between the two systems, including graphic designers knowing that complete, identical matches are impossible. However, printing with Pantone inks can be expensive, so many companies prefer CMYK to save money, even if their logo colors differ slightly.

Meanwhile, Pantone has practically perfected assigning specific codes to all visible colors, so a company that wants the best quality output at every stage of the production process may wish to switch from the CMYK four-color process to Pantone if it intends to invest in the absolute best.

If you want to convert Pantone colors to CMYK or vice versa, Pantone sells conversion guides to help you find the perfect match. Color swatches can be converted using graphic design programs such as Adobe Photoshop or Illustrator.

If you are interested in switching from CMYK to Pantone or the other way around, contact us for a custom quote.

Do You Need Help With Using The PMS?

Creating custom boxes can be easier with our A-Z guide about packaging definitions.

On the surface, PMS appears to be a simple system, but its impact on the industry is evident. When you work with PMS, you can consistently transfer your design from one material to another, which gives you the highest-quality color and exact color matching.

It is also understandable There may still be questions about using the Pantone Matching System, converting CMYK to PMS, and vice versa. As a result, we specialize in CMYK and PMS product packaging design.

We have the knowledge, experience, and expertise to guide you from concept to completion, regardless of your print job size. Professional packaging designers, printers, and graphic artists are available to create and print a design that exceeds your expectations.

Let us help you bring your product to life with beautiful, affordable, and exemplary packaging with the PMS.